How to track performance and uncover opportunities in Supply Chain!

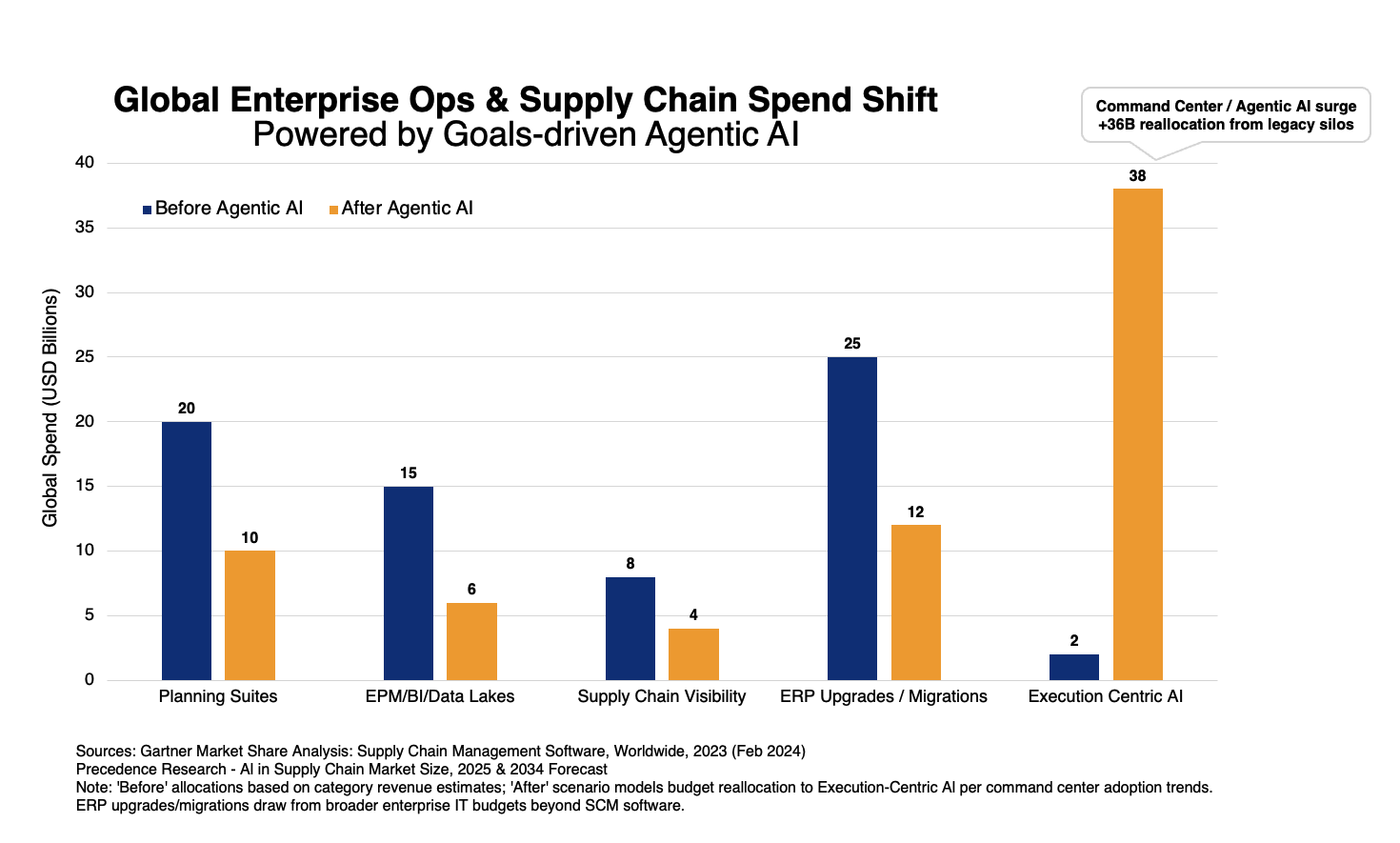

Today’s companies continue to expand to reach global markets, but this has made control of supply chains more and more complex. Companies recognize that developing and executing successful supply chain strategies can be key to gaining a competitive advantage in the marketplace. A key to managing a global supply chain is having strong visibility. This has in turn prompted companies to use technologies such as ERP/MRP systems, warehouse management systems and transportation management systems. Additionally, companies are utilizing hardware technologies, hand-held scanners, GPS, tracking devices, cameras, microphones, RFID readers, wireless networks and automated warehouse systems (AGVs, Robots). Adoption of these technological tools allows more visibility than ever before. But having the data, alone is not enough; managers now have millions and billions of bits of data to decipher and sort through. Having piles of data is not enough, supply chain managers are now faced with how to best use the data to obtain the right information to track performance, diagnose bottlenecks and uncover opportunities for continuous improvement.

Technology has produced mountains of data that if sorted through and arranged properly can help supply chain managers improve efficiency and reduce costs to drive higher profit margins. When managers can identify areas where there are inefficiencies, they are able to focus efforts to improve and therefore cut costs. Excellent data analysis skills have become an important trait of a supply chain manager.

There are six areas of a business where data analytics can be used to manage the supply chain; Inventory and operations planning, Sales, Sourcing, Manufacturing, Warehousing, and Transportation. By gathering information from all these data points, managers get a complete overview of the process from conception to final delivery to customer. A brief look into each area will demonstrate how effective measuring and adjusting bring positive results in cost reduction and customer satisfaction.

Information from sales helps in the process of planning inventory and labor. Understanding what is happening at the point of sale helps managers adjust the supply chain to match supply with demand more closely, additionally it helps to match labor to volumes without disrupting service.

Visibility in sourcing can also help supply chain managers adapt/adjust to changes or events that could negatively affect or disrupt supply at the source. Gathering real time information in critical areas such as transportation, can identify an upcoming event such as a port labor strike, a delay due to a mechanical breakdown of a vessel, plane or truck. Additionally, constant communication and monitoring of suppliers can help identify events that may slow or stop supply at source.

In manufacturing pulling out relevant big data can help identify bottlenecks and drive continuous improvements in various areas within the factory. For warehousing, basic data analysis of typical KPI’s through graphs and charts such as, picks per minute/hour, cost per pick, cartons/skids per hour, distance traveled per pick, can visually help identify positive or negative trends. Additionally, GPS tracking information on incoming trucks make it possible for managers to see possible delays which could cause busy dock schedules to be disrupted. Being able to see what is coming into the warehouse allows for more precise scheduling which greatly improves labor and equipment utilization.

Big data and visibility can also be used to improve transportation. Various devices are now available, such as GPS and handheld devices (iPhone, iPad and similar), that allow the tracking of materials in real time. Many freight carriers have GPS systems installed in units that give real time pin-point information on where materials are on their journey inbound or outbound to destinations.

The key issue to focus on will continue to be the effective organization and relevant use of the huge amounts of data available. Managers must be strong at collecting and putting together measures that effectively give visibility to all areas of supply chain to achieve the supply chains strategic goals.

Regardless of your industry, having a partner to help collect and collate data is vital. OpsVeda can capture your internal data linking them on a continual basis. You have the added advantage of it being delivered on the web and on mobile devices. This allows you to coordinate your data collection regardless of location.