The Real Problem Was Execution - But the Industry Looked at Planning, BI and Visibility

From Reporting Problems to Fixing Them: The Agentic AI Shift Enterprise Ops Can’t Ignore

For years, global enterprises have been haunted by the same operational pain points: late shipments, out-of-stocks, production shortfalls, and margin leakage. In most cases, these were not the result of flawed plans or forecasts, but of execution shortfalls - the inability to adapt fast enough once operations were underway.

Yet the industry rarely framed it that way. Instead, the problem was disassembled into three “solution tracks” that seemed logical at the time:

- Planning suites to produce more accurate forecasts and optimize plans,

- Data lakes and BI platforms to analyze what happened and why, and

- Visibility tools to surface issues earlier in the cycle.

Each category promised to close the gap between expectation and outcome. Each attracted billions in enterprise software spend, propelled by analyst frameworks, vendor roadmaps, and transformation programs. And yet, despite two decades of investment, the “plan vs. actual” gap persists.

The reason is structural: none of these systems were designed to take corrective action in the moment. They could model, report, and alert - but not orchestrate real-time changes across orders, production, inventory, and logistics to actually fix the problem while it was happening.

Agentic AI Moves the Center of Gravity from Plans to Actions

Agentic AI collapses the gap between sensing and response. It’s always-on, stateful, and capable of autonomous decisioning across systems. Instead of waiting for the next planning cycle or an analyst to baby-sit a dashboard, it collaborates and acts: re-allocates inventory, reprioritizes production, chooses a carrier, triggers a supplier escalation, or proposes a price/profit trade-off - and executes within policy.

Gartner analysis underscores the urgency: only 7% of supply chains can execute decisions in real time, yet investment in real-time execution is expected to rise 5x by 2028. This isn’t a tooling tweak; it’s a fundamental budget migration from static analysis to closed-loop action.

At the same time, the industry’s “control tower” story is giving way to command centers - not just visibility hubs, but cross-functional decision engines that fuse insights and orchestration. Gartner projects that by 2027, 70% of enterprises will consolidate planning, visibility, and analytics into a single decisioning layer - precisely the role of execution-centric AI.

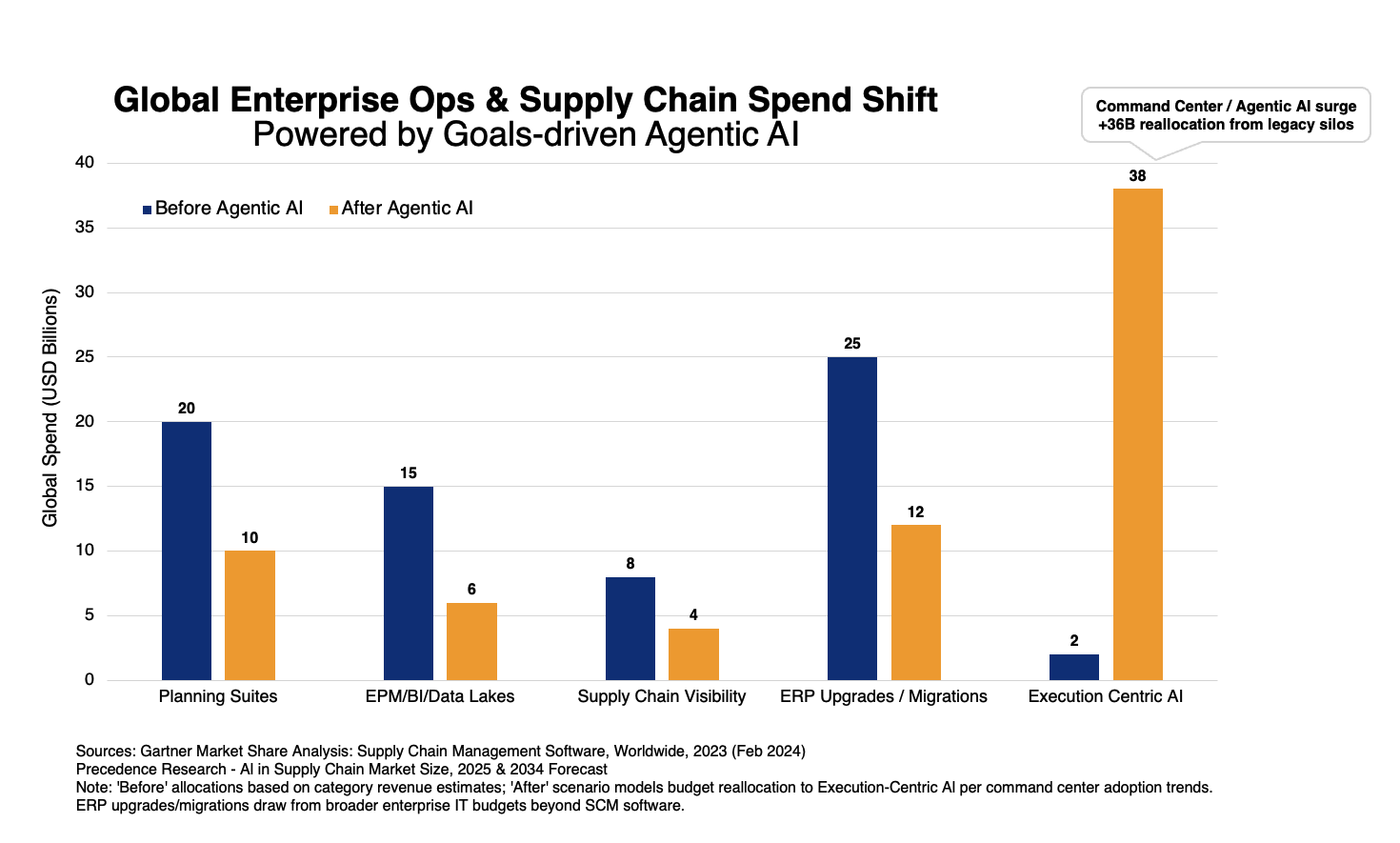

Follow the Money: Where Budgets Go Next

Market sizing makes the shift impossible to ignore:

- Gartner Market Share Analysis (2024) pegs SCM software at ~$29.6B in 2023, growing 13–14% annually.

- Precedence Research projects AI in Supply Chain at ~$9.9B in 2025, exploding to ~$192.5B by 2034 (~39% CAGR).

| Before Agentic AI | After Agentic AI | |

| Planning Suites | $20B | $10B |

| EPM/BI/Data Lakes | $15B | $6B |

| Supply Chain Visibility | $8B | $4B |

| ERP Upgrades / Migrations | $25B | $12B |

| Execution Centric AI | $2B | $38B |

This is not “new” budget - it’s cannibalization. CFOs will cut funding to slow, multi-year transformation tracks (ERP refreshes, planning suite expansions, standalone visibility projects) and redeploy it to platforms that deliver 90-day execution gains in cash flow, service level, and margin protection.

OpsVeda’s 15-Year Investment: From Execution Truth to Goals-Driven Autonomy

OpsVeda was built for the part of the enterprise that actually flows - orders, inventory, manufacturing, logistics - and for the reality that those flows change every minute. From day one, our approach has rested on three design principles:

- Operational truth over perfect models. Ingest and reconcile messy, multi-system data to maintain a live, causal picture of what’s happening now - not last night. This is powered by the Continuous Supply Demand Optimization engine (CSDO) within the Data/AI layer.

- Decision-ability over dashboards. Model decisions (who/what/when/within which constraints) so the system can propose - and now take - actions, not just raise alerts.

- Cross-silo orchestration. Bridge order fulfillment, supply/supplier, inventory, manufacturing, revenue ops, and logistics so fixes propagate end-to-end.

This foundation now powers the Goals-Driven Agentic AI:

- Declare goals, not reports. “Realign supply to match decreased demand ,” “Assess cost of getting from alternate supplier,” “Pull forward revenue in EoM window,” Handle sudden material shortage,” “Prioritize container for aging/backorder-heavy items.”

- Generate policy-safe actions. The agent weighs options (expedite, re-allocate, compress cycle time, rejig priority), simulates scenarios, and executes within guardrails.

- Learn from outcomes. Closed-loop feedback upgrades the policy and the prompts, operationalizing playbooks that were previously tribal knowledge.

Result: a command-center layer that unifies sensing, deciding, and doing - without forcing a new ERP or ripping out existing planning.

Before vs. After: The Enterprise Operating Model

Before Agentic AI:

- Fragmented tools; batch MRP runs; static KPIs; “control towers” that ping humans.

- Long running programs (ERP upgrades, planning re-platforms) chasing theoretical ROI.

After Agentic AI:

- A command center coordinates actions continuously across ERP/WMS/TMS/PLM/portals.

- 90-day lifts in working capital, service level, and cost-to-serve become the default cadence.

- Planning/EPM/BI spend is right-sized; visibility is embedded in execution.

This pattern mirrors external guidance that command centers extend control towers from visibility to orchestration and autonomous execution.

Why OpsVeda Wins This Market

- Native fit with the command center shift. We are not retrofitting dashboards into action; we’ve always been execution-first.

- Faster ROI than ERP or planning expansions. 30/60/90-day outcomes - inventory turns, fill-rate recovery, container prioritization, tariff exposure optimization - fund the deployment from savings.

- Goals-driven autonomy across silos. Not just optimizing one function - optimizing business outcomes enterprise-wide.

- A compounding flywheel. Every executed action feeds back as labeled data, making the agent sharper and the enterprise faster – exactly the compounding effect procurement, manufacturing and logistics leaders want

Objections, Pre-answered

- “Can’t our planning vendor just add this?” Architecturally, batch-centric models and workflow maps aren’t built for continuous, cross-silo action. Retrofitting will be slow and partial. Which planning vendor gets hands dirty with live execution data streams? No, really, which one? (Gartner’s 5x shift to real-time execution underscores the gap.)

- “Do we need to finish our ERP migration first?” No. Command-center layers orchestrate across what you have; ERP becomes the compliant system of record, not the brain - not in the past, not in the future.

- “Isn’t a control tower enough?” Not if it’s just a dashboard. Command centers extend towers to decisioning and execution - the difference between watching a storm and rerouting the fleet.

The Closing Argument to Executives

The industry misdiagnosed execution gaps as planning problems; the cure was more models, more data lakes, more logistics visibility, and multi-year ERP transformations to just get ready for AI!

Agentic AI exposes the flaw and offers the fix: put the brain where the work is, and let it act.

OpsVeda’s 15-year path - operational truth, decision-ability, and cross-silo orchestration - makes our Goals-Driven Agentic AI a credible, immediate way to realize this shift. The market is moving, the budget logic is clear, and the technology is ready.

The next decade of supply chain winners won’t be the best at planning. They’ll be the best at changing course - fast - on purpose.

Stay tuned to our blogs as we continue to share milestones on this transformative journey. If you're interested in exploring how these features can help your enterprise become more responsive and autonomous, get in touch with us.

Let’s build the future of AI-powered Operations - together.